STANDARD SCREENs (over 15l/s)

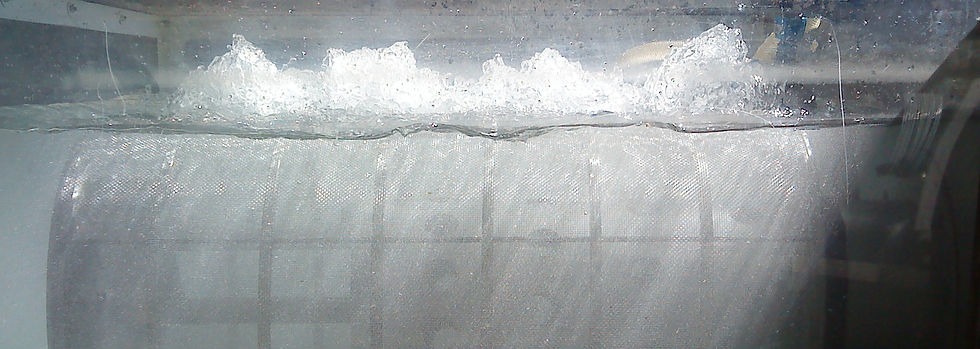

All-stainless construction with thermoplastic bearings, these self-cleaning screens rotate around the intake core, which also houses spray nozzles that backwash debris off the screens. These screens come in a variety of flow rates and sizes.

FEATURES

-

Designed and manufactured for New Zealand and Australian conditions

-

Baffle ensures uniform intake velocity across screen

-

No electrolysis, all materials are stainless steel or plastic, which prevents a corrosive situation with dissimilar metals

-

Durable and relatively light, the stainless steel construction provides a strong and durable screen

-

Dead easy to service

-

Standard connection - the flanges have standard AS 2129 Table E hole dimensions.

DESCRIPTION

Using just 1.8% to 3.75% of the pumped water for backwashing, the screen is continuously cleaned, keeping the system running efficiently and reducing power consumption.

The small screen holes (10 mesh 1.9mm, 20 mesh 0.9mm, 30 mesh 0.6mm) filter incoming water, significantly reducing wear on the pump and other components.

By preventing common issues like screen blockage, loss of prime, and pump wear, maintenance labor is greatly reduced.

Made with durable stainless steel and thermoplastic, it ensures long-lasting performance and meets Environmental Council standards for screen hole size and intake velocity.

FLOW | PRESSURE | CONNECTIONS

DIMENSIONS

HERE WHEN YOU NEED